Home > Wavelengths 800nm-895nm > OsTech > LDX-808NM-100W

$13535.00 sku / item#: LDX-808NM-100W ships: Request a Quote for Current Ship Date

Key Features

- User Adjustable Laser Output 0 to 100 Watts (CW)

- CW and QCW Operating Modes

- TEC-Cooled Internal Laser Mount, Air-Cooled Chassis

- RS232 Interface with LabVIEW Drivers; USB Optional

- PRE-SET FACTORY CONFIGURED LIMITS: Current and temperature limits keep laser diode in safe operating range

Price and Delivery Quote

Technical Questions for this Product

ASK AN ENGINEERCustomers Also Considered:

| MODEL | LDX-808NM-100W |

|---|---|

| PRICE | $13535.00 |

| OPTICAL OUTPUT: LASER DIODE SPECIFICATIONS (TYPICAL @ 25°C) | |

|

|

| CONTROL UNIT LASER DIODE PROTECTION FEATURES | |

|

|

| CONTROL UNIT TEMPERATURE CONTROLLER AND peltier COOLED LASER MOUNTING PLATE SPECIFICATIONS | |

|

|

| QCW pulse and MODULATION specifications | |

|

|

| Fiber Output | |

|

|

| Control Unit / SYSTEM DIMENSIONS AND POWER REQUIREMENT | |

|

|

| USER INTERFACE | |

|

|

Product Overview:

808nm, 100 Watt, Turn-Key Laser Diode Source System Overview

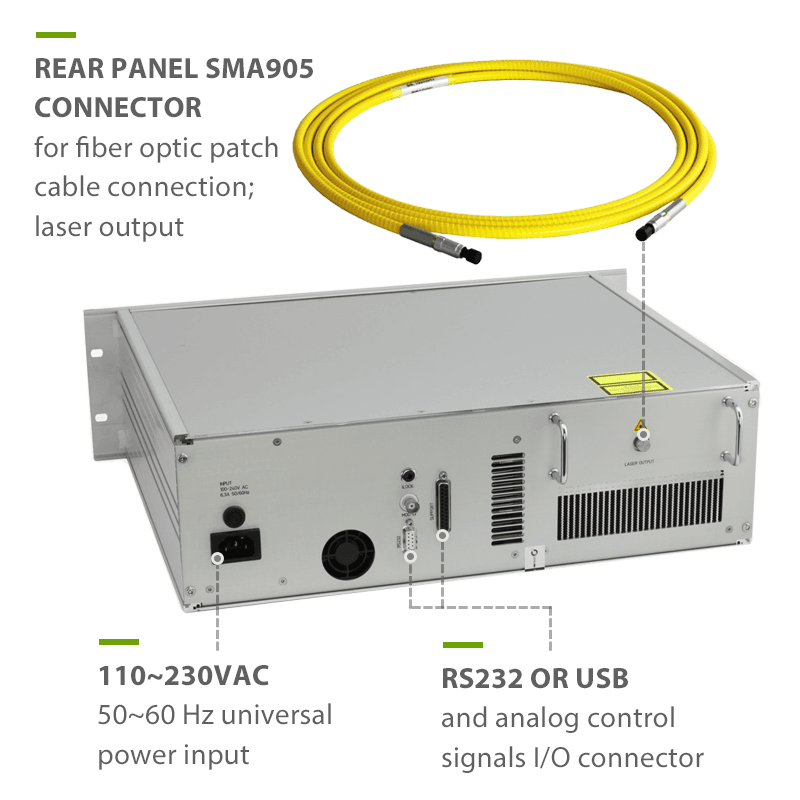

The model LDX-808NM-100W source and control systems are high performance, pre-configured fiber-coupled laser diode systems designed for R&D lab and manufacturing applications. An integrated 100 Watt, 808 nm fiber-coupled source is precisely controlled to provide a high stability output through 200µm-core multi-mode fiber; the output fiber connector is on the instrument back panel.

SIMPLE TO OPERATE: System ships with 808nm laser diode installed and tested in control electronics and mounting module

The LDX-808NM-100W systems include a highly reliable, high power fiber coupled source, a precision high power laser diode current source, and a 336 Watt Peltier / TEC-cooled base laser mounting plate. All system components are integrated into a 3U high, 19 inch wide rack-mount enclosure.

Protection Features Optimized for High Power Laser Diodes:

These source and control systems are built with protection features designed specifically for high power lasers. They are pre-configured with a 300 millisecond soft-start current ramp to the desired laser output power set point. Additionally, the user can set any ramp time period from 300 msec up to 10 seconds. These protection circuits are optimized for lasers with optical output power levels from 50 Watts to 300 Watts. Other protection features include a factory set upper temperature limit and a maximum current and voltage limit. All limits are set to the safe operating range specifications for the specific laser installed in the system.

The LDX series systems have integrated AC power surge clamp circuits to prevent damage from short power brown-outs or black-outs, as well as any potential ESD surges. They also have an open circuit detector and redundant temperature sensors to protect the laser from thermal damage.

Flexible User Controls:

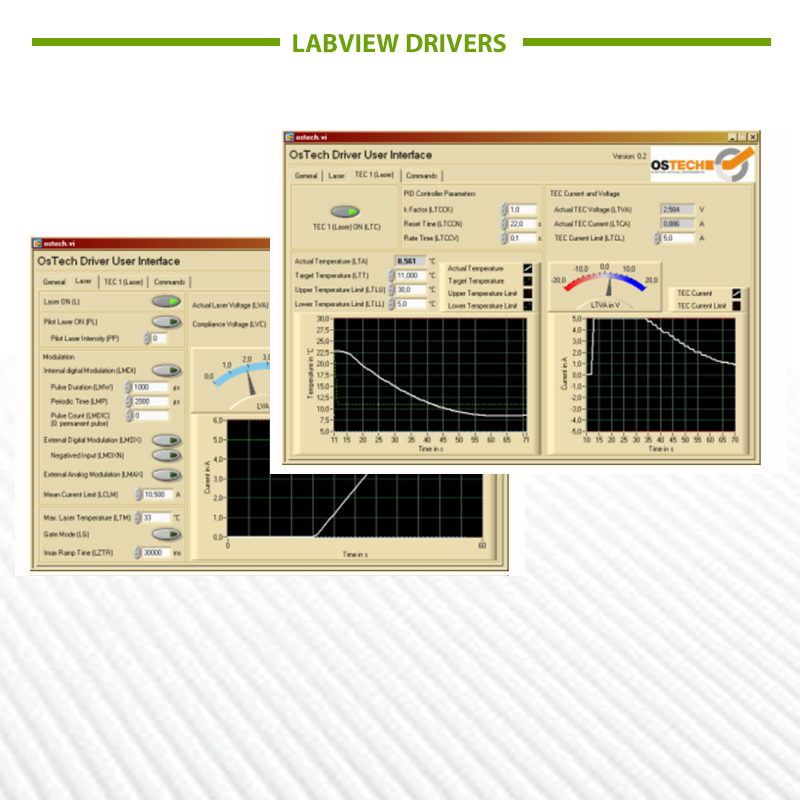

Users have full control of the laser through a touch-key front panel menu and LCD display, or through the rear-panel digital interface. Laser output power can be adjusted in the optical domain (Watts) if the user chooses the automatic power (APC) control mode, or by adjusting the current level (ACC mode). The user also has control over the laser temperature set-point within the safe operating range. The LDX system can be controlled remotely by RS232 or by USB, and includes LabView drivers. Sequencing software is also available for pre-programming multi-step tests.

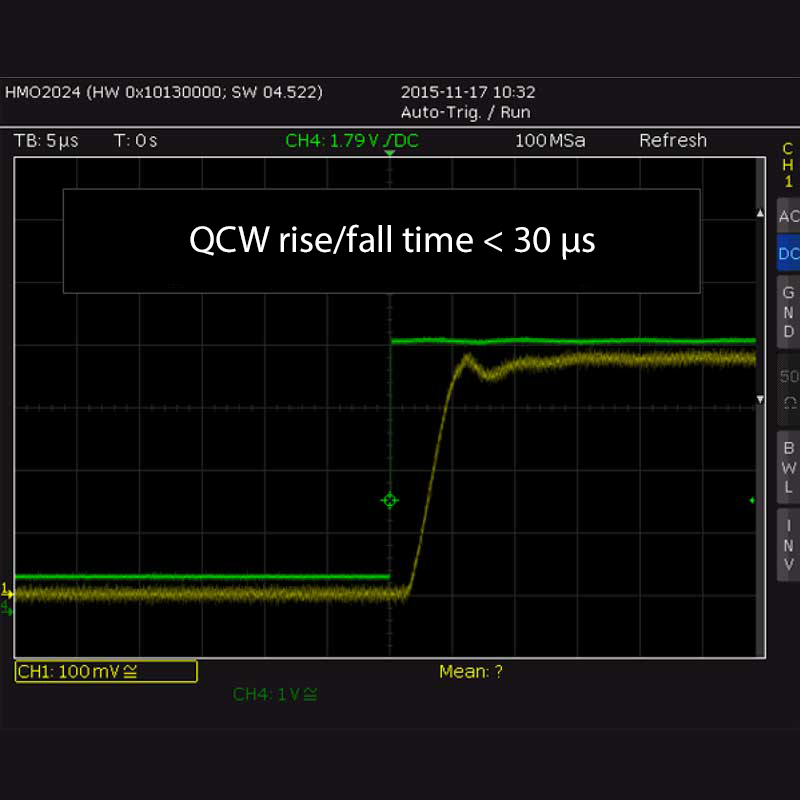

QCW, Modulation, Internal Function Generator:

In addition to CW mode, the LDX series offer QCW and modulation modes. The control unit includes with an internal function generator which can be used to set the quasi-CW pulses. Also, the user can use an external source to trigger QCW pulses. The control unit will accept either TTL or analog modulation.

Primary Applications:

The high power 100W LDX model systems are used in plastic welding, soldering, illumination, selective laser melting, heat treatment, medical and many materials processing applications.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability