Home > Wavelengths 900nm-1190nm > OsTech > LDX-976NM-55W

$8495.00 sku / item#: LDX-976NM-55W ships: Request a Quote for Current Ship Date

Key Features

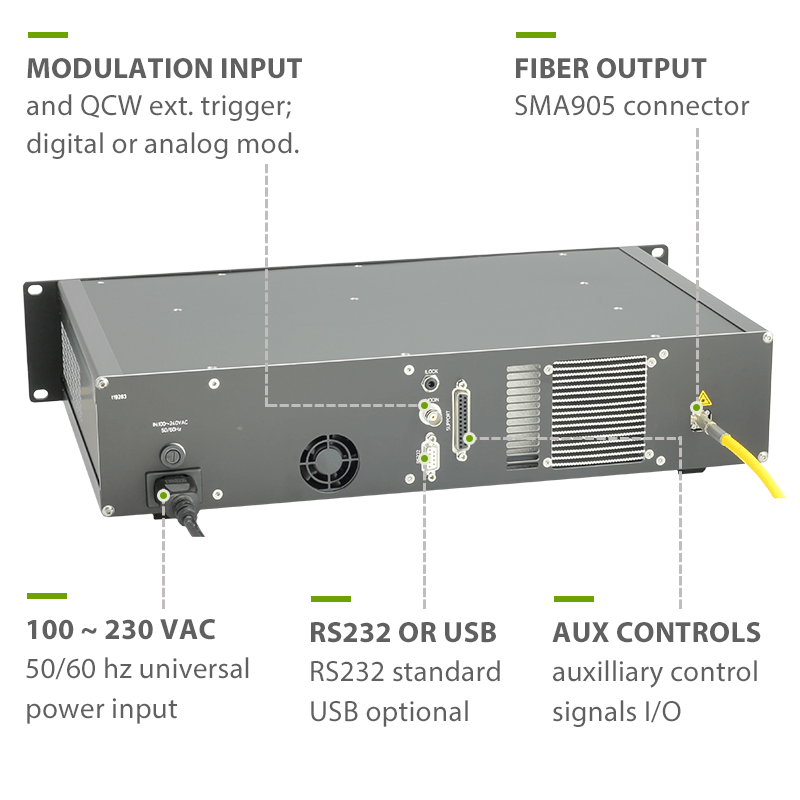

- User Adjustable Output Power 0 to 55 Watts (CW)

- 105 µm Core Fiber; 95% of Power within 0.15 NA

- TEC-Cooled Internal Laser Mount, Air-Cooled Chassis

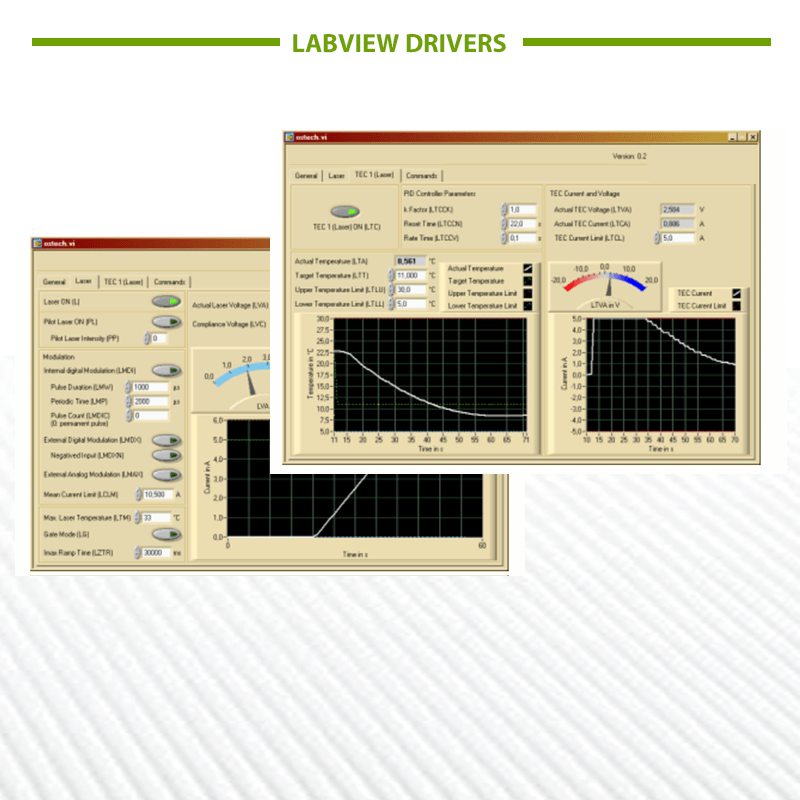

- RS232 Interface with LabVIEW Drivers; USB Optional

- -----------------------------------------------------------------------

- FACTORY CONFIGURED LIMITS: Current and temperature limits keep laser diode in safe operating range

- INSTALLATION SUPPORT: Get up and running fast with unlimited phone & email tech-support; see contact info in the images section to the left

Price and Delivery Quote

Technical Questions for this Product

ASK AN ENGINEERCustomers Also Considered:

| MODEL | LDX-976NM-55W |

|---|---|

| PRICE | $8495.00 |

| Optical OUTPUT: Laser Diode Specifications (typical @ 25°C) | |

|

|

| CONTROL UNIT LASER DIODE PROTECTION FEATURES | |

|

|

| CONTROL UNIT TEMPERATURE CONTROLLER and TEC cooled laser diode mounting plate Specifications | |

|

|

| QCW PULSING MODE and MODULATION specifications | |

|

|

| System Dimensions and Power Requirement | |

|

|

| User Interface | |

|

|

| Fiber Output | |

|

|

Product Overview:

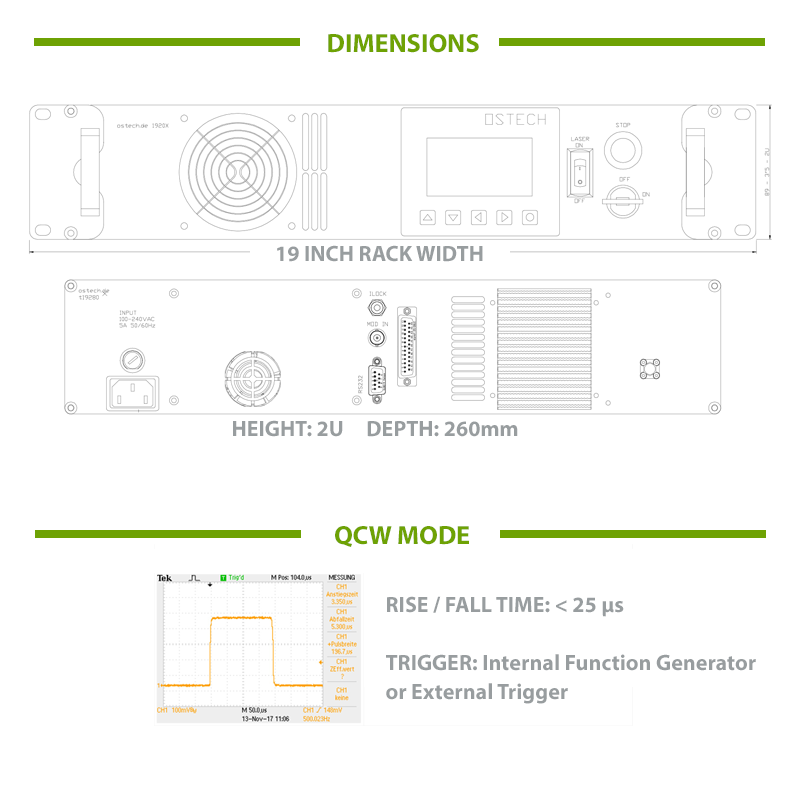

976nm, 55 Watt Turn-Key Laser Diode Source Overview

The LDX-976NM-55W laser diode system is a high performance fully integrated turn-key instrument for R&D and manufacturing applications. It includes an integrated 976 nm high power fiber coupled laser, a high power current source, TEC controller, and a Peltier cooled laser mounting plate assembly. All of these components are integrated into a 19 inch wide, 2U high enclosure. All of the systems settings are pre-configured at the factory and the unit is calibrated with the integrated laser diode. Industry-leading protection features ensure that the laser diode is protected at all times.

User has Complete Control of the 976nm Laser

Users have full control of the fiber coupled laser module power through a touch-key front panel menu and LCD display or through the digital interface. Laser output power is set by adjusting the current level (ACC mode) or adjusting the laser power in watts using the automatic power (APC) control mode. The APC mode utilizes the laser diode's internal monitor photo-diode to feedback to the bias current source. The LDX systems can be controlled remotely by RS232 or optional USB interface, and the system ships with LabView drivers.

Factory-Configured Laser Diode Protection

The LDX-976NM-55W series instruments ship with pre-configured protection settings to make sure that the laser is run safely and operates within the specified maximum operating limits. These limits include the upper current limit and upper temperature limit. Additionally, a soft-start current ramp is set to 300 milliseconds to protect the laser from thermal shock when the bias current is applied. This soft-start ramp time can also be customer configured through the front panel or digital interface. These units also have robust clamping circuitry to protect the laser against power surges and ESD.

TEC Based Temperature Control System

The system employs an integrated high power TEC temperature controller with a full P.I.D. control loop to deliver fast and efficient heat removal from the source laser module. The laser diode is mounted on a Peltier / TEC cooled, nickel plated copper mounting plate. The mounting plate offers very high surface finish and flatness for low thermal impedance. The cooled mounting plate for the laser is attached to a fan cooled air duct to remove the waste heat and keep the laser temperature stable.

Why do Scientists & Engineers Choose Laser Lab Source?

-

Get DIRECT, Fast Tech-Support from the Product Engineer, No Sales Person in the Middle

-

Get the Lowest Price, Factory Direct, No Mark-Up's, Suppliers Post their Own Price

-

Get a 30 Day Evaluation Period with No Risk Return on Most Products, Check Availability